Food

Cereals

Cereals are an important food source for nutrition across

the world.

Size reduction is an important process in cereal process, as

it is used to reduce the size of cereals and other materials in order to

facilitate the grinding and processing of these materials. There are several

methods that can be used for size reduction in the cereal industry, including:

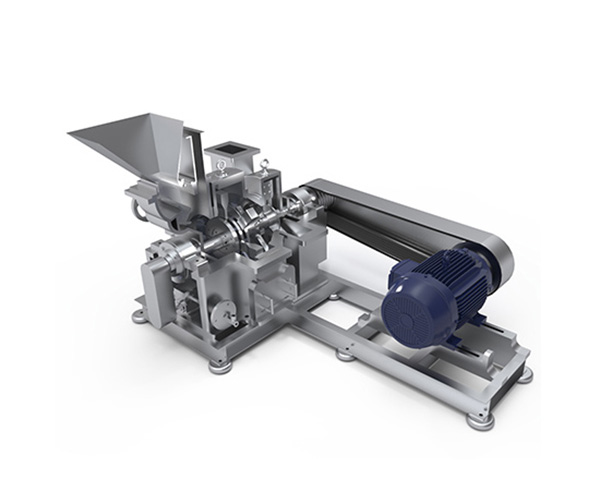

- Crushing: This involves using mechanical force to break the cereals into smaller pieces. This can be done using a variety of equipment, such as DP Hammer Mill and DP Impact Crushers

- Milling/ Pulverizing : This involves using grinding equipment to reduce the size of the cereals into a fine powder. This can be done using a variety of equipment, such as DP Hammer Mill, DP Impact Pulveriser/ Pulverizer and DP Air Classifier Mill

- Sieving: This involves using a sieve or screen to separate the cereal grains based on size. This can be done using equipment such as vibrating screens or air classifiers.

- Extrusion: This involves using high pressure and heat to process the cereals into a variety of shapes and sizes. This can be done using extruders, which are machines that apply pressure and heat to the material to form it into a specific shape.

DP Pulveriser as one of the most reputed and trusted

suppliers of Size Reduction equipment also offers customized solutions for Cereal

Process and Manufacturing.